Introduction

The hospital laundry is mainly responsible for the washing, ironing and replacement of medical reusable fabrics, including patient gowns, bed sheets, quilt covers, surgical towels, medical staff uniforms, etc. Although there is no direct contact with patients, the quality of washing directly affects the medical safety and reputation of the hospital.

The laundry is a department of the hospital. Whether its operation is normal or not depends on the strong support of other departments. In daily work, it is necessary to communicate with the wards and various departments in a timely manner to determine the delivery cycle and time. The normal operation of the hospital should not be affected by the quality of washing and delivery time.

Laundry layout

The location of the laundry should be a separate area and should be arranged according to the relevant process flow. The laundry will generate high temperature, steam, noise, etc. during daily work, which affects the normal operation of the hospital. Therefore, the laundry is usually set up in an independent area, away from the diagnosis and treatment area. If it is large in scale, a single-family ancillary room can be set up. When the laundry is set up on the ground floor or basement of the ward building, effective measures should be taken to avoid noise interference with the ward. There are many types of equipment in the laundry room, which consumes a lot of power. Therefore, its location should be close to equipment rooms such as boiler rooms, pump rooms, and transformer rooms.

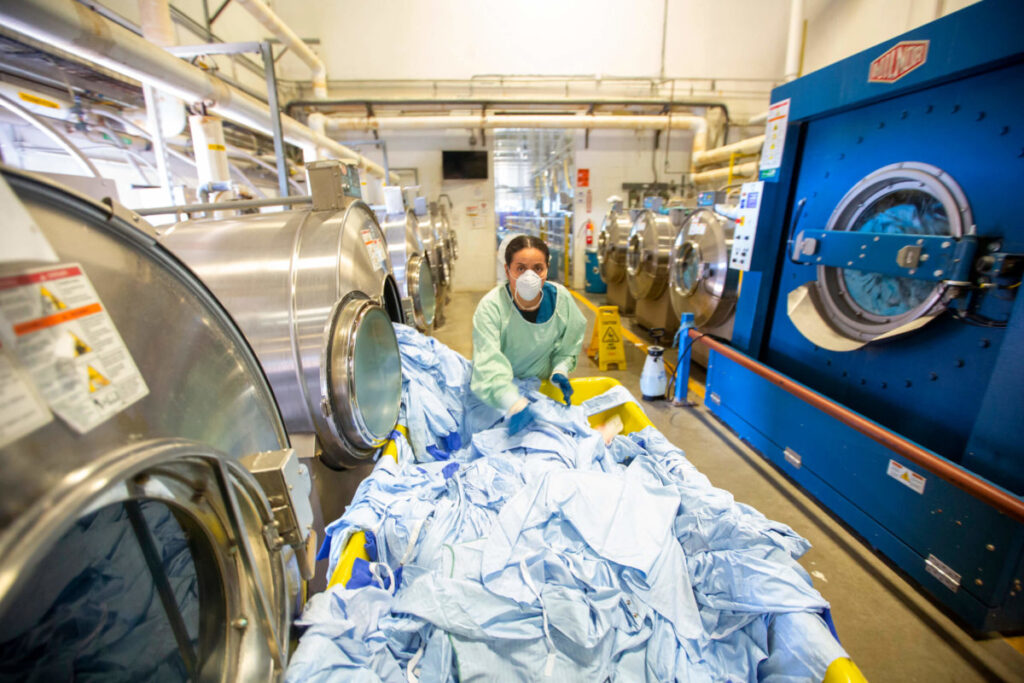

The laundry room should have an office area and a work area. The work area is divided into a contaminated area and a clean area and corresponding passages. There is a strict physical partition between the two areas to avoid air convection. The main function of the contaminated area is to receive and sort contaminated medical fabrics, wash and disinfect them, and store dirty cars; the main function of the clean area is to dry, iron, repair, fold, store, distribute, and store clean cars for medical fabrics. Each area and functional room is clearly marked, and the staff and medical fabrics are received and distributed in dedicated passages, without crossing or going in reverse.

Laundry Management System

1. Staff must undergo pre-job training before taking up their posts, must be proficient in washing and disinfection skills, understand the relevant equipment and facilities such as washing and drying, and the basic knowledge of disinfection isolation and infection control, and the use of common disinfectants. Staff must pass the training assessment before they can take up their posts.

2. Go to and leave work on time. It is strictly forbidden to leave the post, visit other posts, sleep on the post, go to work after drinking, drink on the post, smoke in public places, and engage in activities unrelated to work.

3. It is strictly forbidden for staff to bring personal belongings into the laundry room for cleaning, repairing, ironing and making bedding. It is strictly forbidden to take out hospital scraps for private use.

4. It is strictly forbidden for staff to eat and drink in the work area (especially the contaminated area). Wash hands before entering the work area and eating and drinking.

5. Staff should take personal protection measures. When collecting contaminated cloth items, staff should wear masks and gloves. When counting and handling infectious clothing, masks, hats, gloves and isolation gowns should be worn, and wash hands in time after contact with contaminated items. Staff in the contaminated area should wear work clothes when working, take off work clothes after work, change and wash work clothes once a day, and wash hands and shower when leaving the contaminated area.

6. Be familiar with the cleaning, disinfection, maintenance and maintenance methods of the equipment, and implement the maintenance and maintenance of the equipment as required. Take good care of mechanical equipment, perform regular maintenance on them as required, and do not overload them.

7. When collecting and handing over used medical fabrics and clean fabrics, there should be record documents. The record content should include the name, quantity, appearance, washing and disinfection method, handover time and other information of the medical fabrics, and signed by the quality inspector and the handover personnel. Daily quality inspection records and handover records should be traceable, and the record retention period should be no less than 6 months.

8. All relevant systems, risk responsibility agreements, microbial monitoring reports, and valid certificates (copies) of disinfectants and disinfection equipment used in the laundry room should be filed for reference and updated in a timely manner.

Laundry supporting facilities

1. There should be safety facilities such as rat and fly protection, such as rat guards, fly lamps, etc.

2. Air disinfection facilities should be installed in the contaminated area. In order to facilitate work, it is recommended to install an air disinfector. Disinfection is carried out twice a day, with each disinfection time of more than 30 minutes. Disinfection records should be completed in a timely manner, and the cumulative time should be recorded. Carry out regular maintenance and monitoring according to the manufacturer’s instructions for use of the air disinfector, and establish a maintenance record book.

3. Improve hand hygiene facilities. It is recommended to install non-touch faucet switches in contaminated areas, and configure hand sanitizer, dry hand paper, hand washing charts, etc. Quick-drying hand disinfectants are configured in the clean area, and staff perform hand hygiene before contacting medical fabrics after disinfection.

4. The locker room is equipped with sufficient protective equipment according to work needs, which are placed in a fixed position for easy access and replenished in time after use, including work clothes, work hats, masks, gloves, waterproof aprons and waterproof shoes.

5. According to the number of medical fabrics collected and issued, the dirty and clean carts are reasonably configured, and conspicuous signs are affixed. They should not be used cross-used. They should be cleaned and disinfected in time after use and stored in a fixed position.

6. The configured detergents, disinfectants and disinfection equipment should comply with relevant national regulations.

7. Configure special disinfection equipment for medical fabrics for newborns and infants, and they should not be mixed with other medical fabrics.

8. Complete cleaning utensils including floor towels, cloth towels, containers for disinfectants, chlorine-containing disinfectants and concentration test cards. Cleaning utensils are strictly divided into different areas, clearly marked, and strictly mixed.

Personal protection in the laundry room

1. Dirty area: Staff in the sorting area should wear work clothes and work shoes, masks, work hats, gloves, and waterproof aprons and waterproof shoes when necessary. The isolation area should reasonably select isolation gowns according to work needs. Disposable isolation gowns are prohibited from being reused. Reusable isolation gowns are strictly replaced in one shift and cleaned and disinfected in time after replacement. Strictly implement hand hygiene and wash hands in time after removing gloves.

2. Clean area: Wear work clothes, work shoes, work hats, and keep hands clean.

Workflow of the laundry room

1. Collection: Dirty and infectious fabrics should be collected by classification to reduce shaking. It is prohibited to count in the wards and corridors to reduce secondary pollution to the environment; infectious fabrics are collected directly by the bedside in the ward using orange-red infectious fabric bags. Sorting and counting are prohibited, and they are directly transferred to the isolation laundry room in a closed manner.

2. Transportation: Used medical fabrics should be transported by dirty vehicles, and washed and disinfected medical fabrics should be transported by clean vehicles. Mixing is prohibited and they should be cleaned and disinfected regularly. For transporting infectious fabrics, dirty vehicles should strictly implement one-use-one-disinfection.

3. Washing and disinfection: Check whether the medical fabrics are washed and disinfected by separate machines or batches according to the different users, nature and degree of stains. For example, medical fabrics for newborns and infants should be washed and disinfected by special machines; medical fabrics in operating rooms should be washed and disinfected separately in different time periods; infectious fabrics should not be washed manually. It is advisable to use a special machine for washing and disinfection, and hot washing is preferred; the cabin door and the surrounding area should be wiped and disinfected immediately after each delivery. Special procedures should be formulated for specially contaminated fabrics.

4. Environment: After the work in the contaminated area is completed, the work surface and the ground should be wiped and disinfected with 500mg/L chlorine-containing disinfectant in time. If the sorting area is obviously contaminated with blood or body fluids, first use hygroscopic materials to remove visible contaminants, and then use 2000mg/L chlorine-containing disinfectant to wipe and disinfect; the clean area should be wet wiped with clean water every day to keep it clean and dry. After the cleaning and disinfection work is completed, the cleaning utensils should be cleaned and disinfected in time, hung to dry, and the cleaning and disinfection records should be completed in time. The surface of objects and the hands of staff should be monitored once every six months. The monitoring results should comply with the Class III environment of GB15982, that is, the surface of objects is ≤10cfu/cm2, and the sanitary hand disinfection is ≤10cfu/cm2.

Laundry storage

The storage area should be kept clean and dry, and cleaned and disinfected in time after contamination. After washing, drying and folding, the clean fabrics should be placed on the racks in categories, 20cm~25cm from the ground, 5cm~10cm from the wall, and ≥50cm from the ceiling. Quick hand disinfectant should be used, and hand hygiene should be performed before taking the clean fabrics. If stains, odors, etc. are found, they should be washed again in time.

Laundry washing quality

The washing quality of clean fabrics should be clean, dry, flat, without damage or odor when viewed with the naked eye; when it is suspected that a hospital infection outbreak or cluster infection cases are related to medical fabrics, the cleaned medical fabrics should be monitored for hygiene in a timely manner, including the number and type of bacterial colonies. The qualified standard for monitoring bacterial colonies is ≤200cfu/100cm2, and coliform bacteria and Staphylococcus aureus shall not be detected.

Why Choose Us?

CNMEDITECH is dedicated to the long-term research of the medical consumables market. Our mission is “People oriented and win-win strategy,Matching the real needs of the region with a focus on human health,To be the world’s first-class medical field solution expert”. We have been manufacturing high-quality medical device products for more than ten years.

We have built our reputation on delivering quality healthcare solutions on time and on budget. All our products comply with international health and safety regulations and all products come with a warranty.

Are you still worrying about your customer’s product needs? Are you still angry that the product is expensive?Our medical consumables support personalized product customization.

Our company has many styles to choose from. In addition, we have high-quality pre-sales consulting guidance and professional after-sales service, all to meet your needs.

Whether it is a cost-effective or high-end product, there will always be something suitable for you. If you have any needs for products, you can ask us, our factory will meet your needs as soon as possible, and we will make every effort to provide you with solutions.Feel free to send us your inquiries.