Introduction

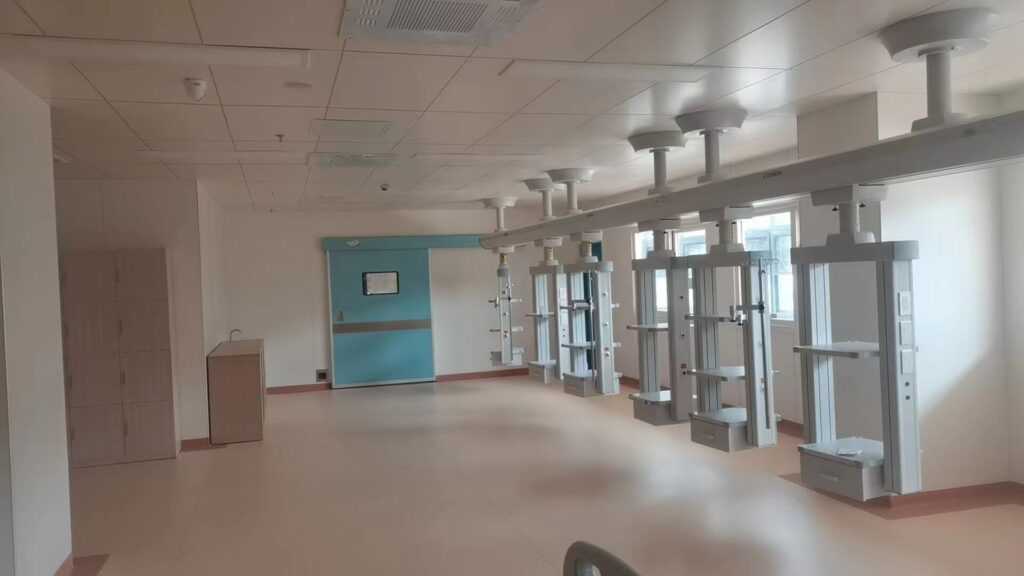

The operating room is a place that provides surgery and rescue for patients. It is an important technical department of the hospital and a key department of hospital infection control. The environment of the operating room is directly related to the quality of each operation and the vital interests of each patient. With the continuous improvement and improvement of surgical medical technology, the environmental and functional requirements for the operating room are also getting higher and higher. Laminar flow clean operating room is the development trend of contemporary hospitals and a symbol of modern hospitals.

The modern operating room is the department with the most stringent requirements and the most complex structure in the hospital. It not only provides equipment support for the surgical process, but also meets the requirements for environmental temperature, humidity, pressure, wind speed, noise, illumination, and cleanliness during the operation. Professional design can make the system reliable, practical, economical and convenient, and generate greater economic benefits for the hospital.

Design ideas

People-oriented, clean and polluted diversion, energy saving and emission reduction, complete functions, flexible and universal. The layout of the clean surgery department is a single corridor layout, fully considering the rationality and practicality of the flow of people and logistics channels. And the operating department is divided into several operating areas according to different departments, fully integrating surgical resources and improving surgical turnover efficiency.

Cleaning the surgical department should not only create a good medical environment, but also create a comfortable and comfortable environment for work and rest. We no longer blindly pursue the number of operating rooms, but fully increase the number and area of auxiliary rooms and office rooms on the premise of meeting usage needs to provide a good rest and office environment for medical staff.

Main equipment of clean operating room

1.Shadowless lamp and hanging tower bracket: 1 set each/each operating room

Made of steel above 12mm, including bolts and other accessories.

2.X-ray viewing light box 1/each operating room

100-level operating room: 6 units; 10,000-level operating room: 4 units, LED sensor backlight for film viewing.

3.Built-in medical gas box-1 1 set/each operating room

German standard, in line with DIN standards, all plugs are non-interchangeable; each gas pipeline in the terminal box is equipped with a shut-off valve. Port configuration: 2 channels of oxygen, 2 channels of negative pressure, 1 channel of air, 1 channel of carbon dioxide, 1 channel of nitrogen, 1 channel of laughing gas, 1 channel of anesthesia waste gas output port. It must have 2 self-closing air locking functions, with plug-in and pull-out parts, and each terminal is equipped with a plug-in and pull-out part.

4. Built-in medical gas box-2 2 sets/each operating room

German standard, in line with DIN standards, all plugs are non-interchangeable; each gas pipeline in the terminal box is equipped with a shut-off valve. Port configuration: 1 oxygen, 1 negative pressure, 1 air, 1 carbon dioxide, 1 nitrogen, 1 laughing gas, 2 self-locking gas functions.

5.Built-in anesthesia cabinet 1/each operating room

Made of stainless steel, the upper cabinet is about 1100W*600H*350D; the lower cabinet is about 1100W*900H*600D, and the lower cabinet has a stainless steel countertop.

6.Built-in medicine cabinet 1/each operating room

Made of stainless steel, the upper cabinet is about 1100W*600H*350D; the lower cabinet is about 1100W*900H*600D, and the lower cabinet has a stainless steel countertop.

7.Embedded instrument cabinet 1/each operating room

Made of stainless steel, the upper cabinet is about 1100W*600H*350D; the lower cabinet is about 1100W*900H*600D, and the lower cabinet has a stainless steel countertop.

8.Combined power socket box-1

2/each operating room, made of 1.2mm stainless steel, each group has 3 220V 10A sockets, 1 220V 16A socket, with 2 equal potential sections, concealed installation.

9.Combined power socket box-2

1/each operating room, made of 1.2mm stainless steel, each group has 1 380V 10A socket, 3 220V 10A sockets, with 2 equal potential sections, concealed installation.

10.Equipotential grounding box 1/each operating room

Made of 1.2mm stainless steel, internally equipped with 40*4 copper bars, including no less than 8 terminals

11.Dedicated purification air supply ceiling 1/each operating room

Equipped with H13 partition-less low-resistance high-efficiency filter, the filtration efficiency is ≥99.99% for particles ≥0.5 microns.

12.Operating room exhaust vent 1/each operating room

Equipped with F7 medium efficiency filter

13.Medical purification lamps 10 to 12 groups/each operating room

Class 10,000: Equipped with electronic ballast, factor greater than 0.95, 3 light sources, 1 loop in the middle, 1 loop on both sides, door rocker switch, touch screen control.

Level 100: LED light source.

14.1 set of warming cabinets and refrigeration cabinets/2 units each in the 100-level operating room and the aisles on the 3rd and 4th floors

15.IT isolation transformer 1 set/each operating room

16.Ceiling infusion rails and hangers 2 pieces/each operating room

Linear guide rail, length 2.6m, equipped with 4 lifting hooks.

17.Induction electric single opening sliding door

The door body is made of stainless steel panel, the door opening size is 1500*2200, and the 1.2mm thick 304 stainless steel door cover. The transmission form is cam track crawler type, with long service life, simple, safe and convenient operation and maintenance. It is treated with rubber sealing strips and is completely sealed when closed. It should have emergency manual door opening function, anti-pinch and anti-collision; the induction device is fully equipped The light control and door operator systems are required to be imported with original packaging, each with an observation window of 800*600, with normally open function, panel control, half-open and full-open, normally open, and outdoor half-open. Installation method: The entire door body is embedded in the wall and is flush with the wall surface. An “In-Operation” display light is set on the electric door of each operating room. Operating room doors that require radiation protection treatment also need to meet corresponding radiation protection requirements.

18.Steel sliding door for auxiliary room

0.8mm thick steel plate spray-coated door body with window; aluminum alloy door cover. Including door locks, imported door closers, door catches and other hardware accessories.

19.Operating room swing door

0.8mm thick steel plate spray-coated door body with window; aluminum alloy door cover. Including door locks, imported door closers, door catches and other hardware accessories.

20.Corridor swing doors

0.8mm thick steel plate spray-coated door body with window; aluminum alloy door cover. Including door locks, imported door closers, door catches and other hardware accessories.

21.Stainless steel induction wash basin

22.Medical equipment belt

1 set/per bed, used for preoperative preparation and recovery room. Gas per bed: 2 oxygen, 2 negative pressure, 2 air, with two self-closing air locking functions. 2 information terminals and 3 5-pin universal power sockets.

23.Operating room intelligent LCD information panel: 1/each 100-level operating room

Microcomputer LCD touch type, displays the air conditioner’s air return temperature, filter pressure difference, indoor and outdoor pressure difference; clock display (anesthesia time, operation time, Beijing time); operating status and fault indication of air conditioner and exhaust fan; water valve, The opening size of the damper and fault indication. Control the sub-lights and main lights of the shadowless lamp respectively, and control the lighting in the operating room to turn on one-third, two-thirds, fully on, and fully off. It can control the opening of the operating door to fully open, half open and fully close, and is linked with the purification air conditioner and exhaust fan. Each time the door is opened, the lighting fixture can be fully closed to open one-third of the light source. Control the switch of background sound, etc. Provide free interfaces, open protocols and cooperate with debugging.

24.Touch information panel 1 set/each 10,000-level operating room

The surface of the microcomputer is touch-sensitive, displaying the air conditioner’s air return temperature, filter pressure difference, and indoor and outdoor pressure difference; clock display (anesthesia time, operation time, Beijing time); operating status and fault indication of the air conditioner and exhaust fan; water valve, The opening size of the damper and fault indication. Control the sub-lights and main lights of the shadowless lamp respectively, and control the lighting in the operating room to turn on one-third, two-thirds, fully on, and fully off. It can control the opening of the operating door to fully open, half open and fully close, and is linked with the purification air conditioner and exhaust fan. Each time the door is opened, the lighting fixture can be fully closed to open one-third of the light source. Control the switch of background sound, etc. Provide free interfaces, open protocols and cooperate with debugging.

25.Single air conditioning control panel 1 set/each unit in the corridor auxiliary room

The microcomputer surface is touch-sensitive, with functions such as temperature and humidity display and setting, on/off, air conditioner operating status display, fault alarm, and filter alarm.

Indoor temperature and humidity

Appropriate temperature is necessary to maintain the patient’s body temperature; indoor temperature and humidity are mainly to create the most comfortable environment for medical staff to work and meet the strict requirements of the surgical process. Low humidity will produce static electricity and cause water loss in the soft tissue of the incision, while high humidity will cause discomfort and affect fine operations.

Indoor air cleanliness

Improving the cleanliness is conducive to enhancing the self-purification ability and resisting interference; using a medical and sanitary unit with margin, a specially designed pressure head, and a patented leak-proof air supply ceiling, which is the first choice of leak-proof ceiling in clean operating rooms First time application. We have used this kind of air supply device extensively in the clean blood ward project. Its uniform flow effect is very good, it can obviously prevent leakage and greatly reduce the air supply volume. Through this specially optimized replacement air flow, the cleanliness of the mainstream area of the operating room is improved by more than an order of magnitude. It is determined that except for the clean operating room, which selects cleanliness level II, the clean corridors and auxiliary rooms are all level 100,000. The number of ventilations: 25 times/h in the first operating room, 32 times/h in the second operating room, and 17 times/h in the auxiliary room and clean corridor.

Indoor positive pressure

In order to prevent external polluted air from entering the operating room and clean area and maintain indoor cleanliness requirements, each room is designed to have positive pressure according to regulatory requirements. Since the operating room uses a medical airtight door, the fresh air volume is large, and the positive pressure value required by the specification can be guaranteed.

Indoor noise

Reasonable selection of pipe wind speed, optimization of air duct pipeline design, improvement of air duct processing technology, use of efficient and clean mufflers, and use of patented leak-proof air supply devices.

Fresh air volume

The amount of fresh air plays a vital role in maintaining positive indoor pressure, diluting and eliminating harmful gases in the operating room, and ensuring the comfort of doctors and patients.

Use shared air conditioning units in operating rooms, clean corridors and auxiliary rooms

In order to reduce the infection rate as much as possible, isolation is an important principle in the design of purified air conditioning in the operating department. The return air in the operating room enters the unit through its own air duct, and then passes through high-efficiency filtration to form the supply air. Each operating room is an independent small circulation air-conditioning system. A part of it is directly discharged, and then the indoor air is extracted by the purification air-conditioning unit, and then a certain amount of fresh air is supplemented. After being processed by the unit, it is sent to the operating room to avoid cross-infection caused by the mixing of bacterial air from other operating rooms.

The airflow organization in the operating room is from the upper to the lower side. Set up a leak-proof air supply ceiling in the center of the operating room and directly above the operating bed. The static pressure box is equipped with a uniform flow orifice plate, which has a good static pressure effect: the operating bed and the first working area where the medical staff are located are directly enveloped in the clean air flow sent out.

There are damping return air inlets at the bottom of both sides of the operating room, which can quickly remove polluted air in the direction of dust settlement, suppress secondary dust, make the return air even, fully benefit the mainstream area, and minimize the vortex area.

Use centralized fresh air and independent exhaust unit

This can ensure that pollution is avoided, clean outdoor fresh air is selected, and sufficient amount is sent to each purification system; at the same time, excess indoor gas is eliminated. The fresh air fan is equipped with primary and medium-efficiency filters, and performs cold, heat and humidity treatment to reduce the burden on the purification host and high-efficiency filter; the outside of the exhaust fan is equipped with a rainproof air outlet and a sub-high-efficiency filter. This prevents the indoor air from being polluted by outdoor air due to natural circulation when the system is shut down.

Adopt automatic air valve, frequency conversion control, air duct electric heater, electrode humidifier

Purifying air conditioning is a constant air volume system, and indoor cleanliness is mainly guaranteed by the number of air changes, that is, the air volume. The system adopts three-stage filtration. During the operation of the system, the system resistance will change due to dust accumulation on the filter, which will change the system air volume and thus affect the purification effect. Therefore, an automatic air valve is used, which is controlled by a microcomputer to automatically adjust the air volume. At the same time, frequency conversion technology is used to make the operating room more flexible and greatly save operating costs. When individual operating rooms are out of service, only the duty air volume can be maintained. As auxiliary heating, the duct electric heater can quickly heat up the operating room after the system is turned on, shortening the preparation time for surgery. It can also be combined with a surface cooler for humidity treatment.

Use primary pump, two-way electric valve and bypass pipe to adjust variable water volume

The system adopts an open circulation system, equipped with an air-cooled heat pump, to adjust the water volume of the air-conditioning unit, and to adjust the water temperature of the entire system. This dedicated system is stable and reliable, and effectively ensures the continuity and safety of the operating department.

The purification unit is located in the upper room to save infrastructure investment.

Why Choose Us?

CNMEDITECH is dedicated to the long-term research of the medical equipment market. Our mission is “People oriented and win-win strategy,Matching the real needs of the region with a focus on human health,To be the world’s first-class medical field solution expert”.We have been manufacturing high-quality medical device products for more than ten years.

We have built our reputation on delivering quality healthcare solutions on time and on budget.All our products comply with international health and safety regulations and all products come with a warranty.

Are you still worrying about your customer’s product needs?Are you still angry that the product is expensive? We have various medical equipment and support personalized product customization.

Our company has many styles to choose from.In addition, we have high-quality pre-sales consulting guidance and professional after-sales service, all to meet your needs.

Whether it is a cost-effective or high-end product, there will always be something suitable for you.If you have any needs for products, you can ask us, our factory will meet your needs as soon as possible, and we will make every effort to provide you with solutions.Feel free to send us your inquiries.