Drainage and Electrical Requirements for Small Hospitals

Introduction

With the continuous advancement of medical technology and the increasing medical needs, infrastructure management of small hospitals has become increasingly important. The formulation of a series of regulations and standards will help ensure that the hospital’s infrastructure can operate safely and effectively. The infrastructure of small hospitals, including hospital buildings, rooms, electrical, water conservancy, energy, lighting, air conditioning and other hardware facilities, as well as related software and hardware, management personnel and maintenance engineering personnel, is an important prerequisite for completing medical services and Support is the basic guarantee for the normal operation of the hospital. Hospital infrastructure management regulations are a series of rules and standards established to regulate the operation and maintenance of these facilities.

Drainage Requirements

Waste Water Management:Small hospitals should have a well-designed and functioning sewage and wastewater management system to handle the disposal of medical and non-medical waste water.

The system must comply with local regulations to prevent environmental contamination and the spread of diseases.

Infection Control:Hospitals must implement infection control measures to prevent the spread of infections through the drainage system.Regular maintenance, cleaning, and disinfection are crucial.

Proper Drainage Design:Ensure that the hospital’s drainage system is designed with proper slopes, pipe sizes, and materials to prevent blockages, backflow, and flooding.

Adequate floor drains should be installed in clinical areas to manage spills and cleaning.

Medical Waste Management:Separate and manage medical waste and hazardous materials according to local regulations and guidelines.

Install designated disposal areas for biohazardous waste.

The main pollutants contained in the sewage of small hospitals are pathogens (parasitic eggs, pathogenic bacteria, viruses, etc.), organic matter, floating and suspended solids, etc. The main departments and facilities that discharge sewage in the project include: diagnosis and treatment rooms, laboratories, wards, radiation Drainage from departments and operating rooms; domestic sewage discharged by hospital administration and medical staff, etc.

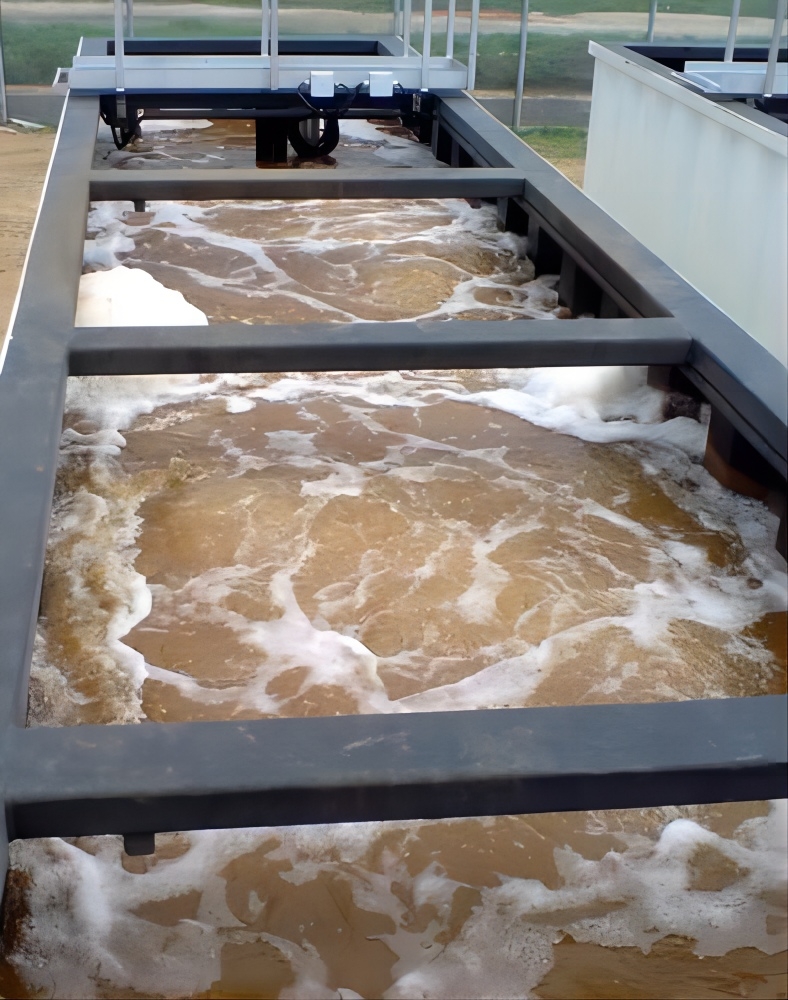

After the wastewater is pre-treated in the septic tank, it is collected into the grid tank through the sewage pipe network. It is intercepted by the grid in front of the tank to remove a large number of floating objects and suspended matter and other impurities entrained in the sewage, and then enters the regulating tank to remove most of the solid matter. and suspended impurities, degrading some pollutants. The effluent from the regulating tank flows automatically into the anaerobic and contact reaction tank, and the pollutant degradation capabilities of different microbial communities in different environments are used to completely degrade the pollutants in the wastewater. The effluent is separated from mud and water in the sedimentation tank, disinfected and sterilized, and then discharged to meet standards. The sludge in sedimentation tanks and septic tanks should be disinfected and sterilized before being removed. After cleaning and drying, the sludge should be disposed of by a unit with hazardous waste disposal qualifications.

At present, regardless of whether it is a city or a town, except for large hospitals that are equipped with specialized medical wastewater treatment systems, most medical institutions such as social welfare, clinics, and small private hospitals are not equipped with such systems. The medical wastewater generated daily by these institutions is directly discharged into municipal sewage pipes. Nets or natural waters, causing a series of environmental pollution problems. With the strengthening of social awareness of environmental protection, although some institutions have installed ultraviolet sterilization and disinfection equipment, it is difficult to ensure that environmental protection emission requirements are met. There are already many medical wastewater treatment equipment on the market. However, the treatment process is simple, the function is single, the operation is cumbersome, and the operation and management are inconvenient. The quality of wastewater in different types of institutions changes greatly, and it is difficult to operate normally to achieve medical wastewater treatment standards in the true sense emission.

There are many technologies for existing sewage treatment equipment in small hospitals. Generally, they have a single function and focus mainly on disinfection. The technologies used include ultraviolet disinfection, activated carbon adsorption, chemical disinfection, etc. The shortcomings of these processes are: for example, the ultraviolet disinfection method has limited wastewater residence time and ultraviolet disinfection range. It is difficult to completely eliminate all germs at one time. Once the germs survive, they will continue to multiply and cause secondary pollution; the adsorption capacity of activated carbon is limited. Limitation, it is difficult to determine the duration of adsorption. In addition, the replaced activated carbon contains a large number of viruses and bacteria, which is troublesome to handle. The chemical disinfection method is currently used more often, and the disinfection effect is better. The disadvantage is that the chemical is difficult to mix evenly with the wastewater, followed by The linkage design between the dosing pump and the water inlet pump makes it difficult to control the amount of medicine added. It is easy to cause insufficient dosing, resulting in insufficient disinfection effect, or overdosing, causing secondary contamination of the medicine.

Electrical Requirements

Hospitals have very high requirements for the reliability of power supply. According to regulations, emergency department rooms, intensive care units, operating departments, delivery rooms, baby rooms, purification rooms of blood wards, hemodialysis rooms, pathology rooms at county (district) level and above are required. The power and lighting of slice analysis, CT scanning room, regional central blood bank, hyperbaric oxygen chamber, accelerator room, treatment room and blood distribution room, incubator, refrigerator, and incubator are first-level loads, and the power supply of electron microscope and passenger elevator are Electricity is a secondary load. Once the above power is cut off, it will have a great impact on medical work, even cause medical accidents and endanger patients’ lives. Therefore, hospitals should use two power supplies for power supply. A common practice is to use dual power supplies. Both channels can supply 100% of the load, and when one channel is repaired or malfunctions, the other channel will not lose power. If restricted by conditions, the following buildings should have their own power supply:

(1) All rooms in the emergency department;

(2) Purification rooms and hemodialysis rooms in intensive care wards, delivery rooms, baby rooms, hematology wards; operating departments, CT scanning rooms, accelerator rooms and treatment rooms, blood distribution rooms, as well as incubators, refrigerators, incubators and others must be continuous Powered precision medical equipment;

Some special places in the hospital have special requirements for power distribution. The power supply of medical equipment in the radiology department should be separately connected from the substation; the power supply of medical equipment in the radiology department, nuclear medicine department, functional examination room and other departments should be equipped with main gates to cut off the power supply. Knife; ICU and operating department power distribution loads generally use dual-channel power terminals to mutually transfer.

The central surgery department is the core of the hospital, and the power distribution in the surgery department adopts dual-channel power terminal switching. This includes the power distribution in the operating room and the power distribution of the clean air conditioning system in the operating room. The power supply is provided by the dedicated line of the substation.

For hospitals that treat infectious patients, the following practices should also be noted:

(1) Electrical loads such as suction, sewage treatment, incinerator, central supply, mortuary, and inspection must use dedicated power lines.

(2) A dedicated transformer is used for air-conditioning load power, which is separated from the distribution and lighting transformer.

(3) The ventilation equipment in the respiratory infectious disease ward should be powered by a dedicated line and controlled centrally at the nurse station.

(4) Where the pipeline trough or bridge passes through the partition wall, it should be sealed to prevent cross-infection of patients.

Conclusion

In summary, the proper management of drainage and electrical systems is critical for the safe and effective operation of small-scale hospitals.Compliance with local regulations, safety standards, and guidelines is essential to ensure the well-being of patients and the functionality of the facility. Routine maintenance, inspections, and staff training are key components of achieving and maintaining these requirements.

Why Choose Us?

CNMEDITECH is dedicated to the long-term research of the medical equipment market. Our mission is “People oriented and win-win strategy,Matching the real needs of the region with a focus on human health,To be the world’s first-class medical field solution expert”.We have been manufacturing high-quality medical device products for more than ten years.

We have built our reputation on delivering quality healthcare solutions on time and on budget.All our products comply with international health and safety regulations and all products come with a warranty.

Are you still worrying about your customer’s product needs?Are you still angry that the product is expensive? We have various medical equipment and support personalized product customization.

Our company has many styles to choose from.In addition, we have high-quality pre-sales consulting guidance and professional after-sales service, all to meet your needs.

Whether it is a cost-effective or high-end product, there will always be something suitable for you.If you have any needs for products, you can ask us, our factory will meet your needs as soon as possible, and we will make every effort to provide you with solutions.Feel free to send us your inquiries.